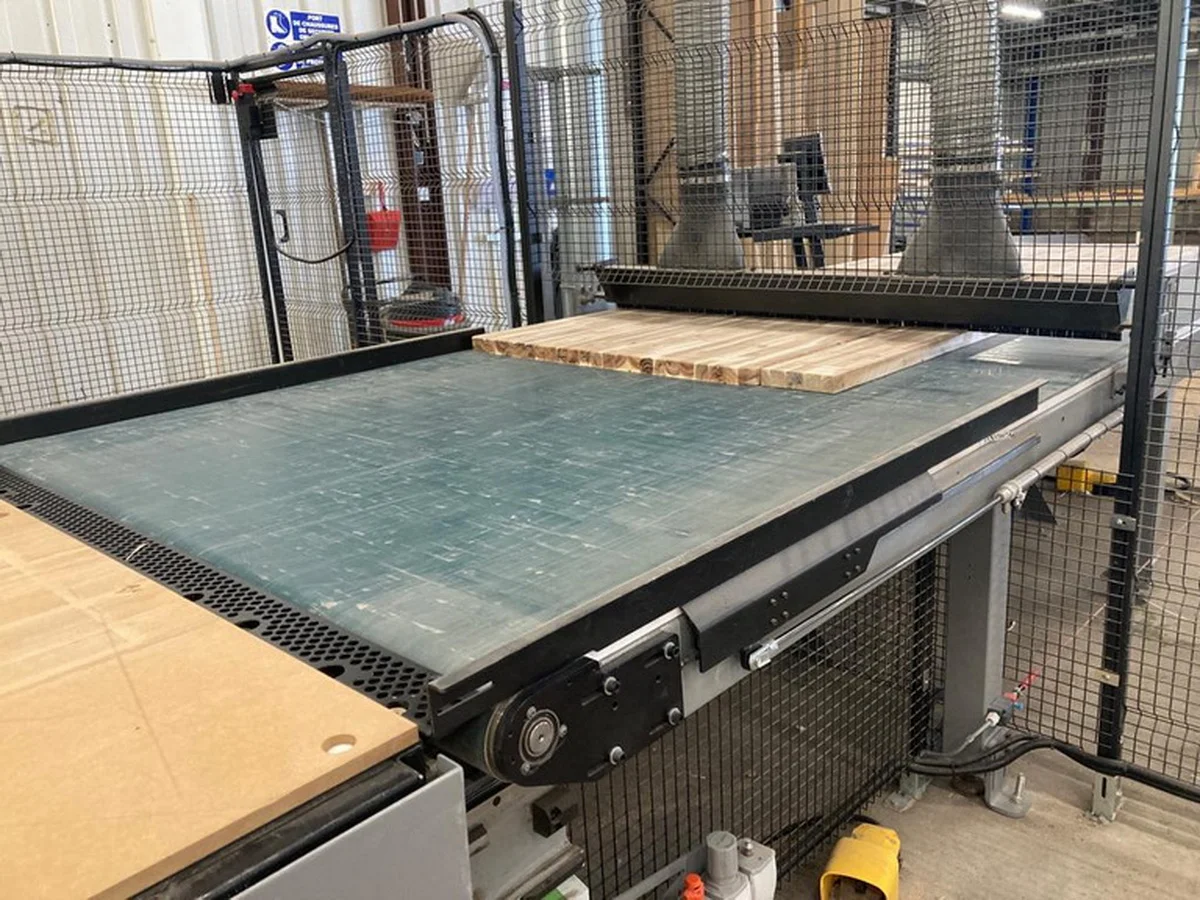

BIESSE Rover A FT 1531

BIESSE

Rover A FT 1531

Price: POA

Technical details:

"NESTING" CELL with 4-axes (X-Y-Z-C) CNC working Center, composed by:

K09040A) AUTOMATIC LOADING/IN-FEEDING SYSTEM (type B) also for thin panels, with scissortable, movable arm (Sweeping Arm) with vacuum suction cups,

K09040B) CNC "nesting" (flat table) "BIESSE" Mod. Rover A - FT 1531Gantry-drive (axe X) machineNumerical Control BH660 (WRT) with Software bSolid (3D CAD-CAM) + bNestSafety cabin (enclosure) of the working head BumperUnique flat working table FTAutomatic Tools Changing System with two (2) Tools storage plates1st Tools storage plate with 16 folds (on X axe) + the 2nd (revolver-type) with 8 folds (on Y-axe)

Max. useful working area (X - Y - Z) mm 3100 x 1560 x 170No. 8 Working areas (Multizone) - No. 3 Vacuum pumps (capacity 250 m3/h each)Separate electric and command cabinet - Total installed power (Kw) 39,45

WORKING GROUPS (TOP):No. 10 Independent vertical boring spindles (5 in X + 5 in Y)Drilling head BH 10 motor-power (Kw) 3No. 1 Aggregate HSK F63 as Circular Saw (max. diam mm 215)No. 1 Vertical electro-spindle HSK F63 (C-axe at 360° - MK259), motor power (Kw) 19,2

K09040C) AUTOMATIC OUT-FEEDING SYSTEM (type 1536) with motorised belt (length mm 4410)